Whether you spotted one in your own neighborhood or saw one while driving into town, you’ve probably noticed the purple streetlights that are cropping up all over America. Street lights vary in color depending what kind of bulb is used. Most street lights are yellow, but long-lasting orange colored sodium lights are also popular. Whiter LED lights are now available, but why purple? It turns out the purple lights raise awareness of a very important issue.

You’ve probably read in the news how very wealthy individuals avoid paying income tax through questionable tax arrangements, offshore accounts or even outright fraud, but did you know that the rich manage to avoid property taxes too? A study of property taxes nationwide found that properties valued in the lowest 10% in a community are typically taxed at a rate 33% higher than properties valued in the top 10%.

How is this possible? The answer is property tax appeals. Wealthy landowners can typically afford to hire law firms to challenge the valuation of their properties. The tax assessor then has a choice: they can put up a fight against a wealthy, well-connected campaign donor, or they can give up and get another campaign donation for their reelection. Even when the tax assessor isn’t elected, they report to someone who is. Unsurprisingly, the tax assessor usually gives the rich what they want. It’s not hard to make an appeals system that is hard for ordinary citizens to navigate but easy for a well-funded lawyer, so that’s usually how they do it. Poor landowners simply don’t have the time to challenge their assessments, so they pay too much while the rich pay too little.

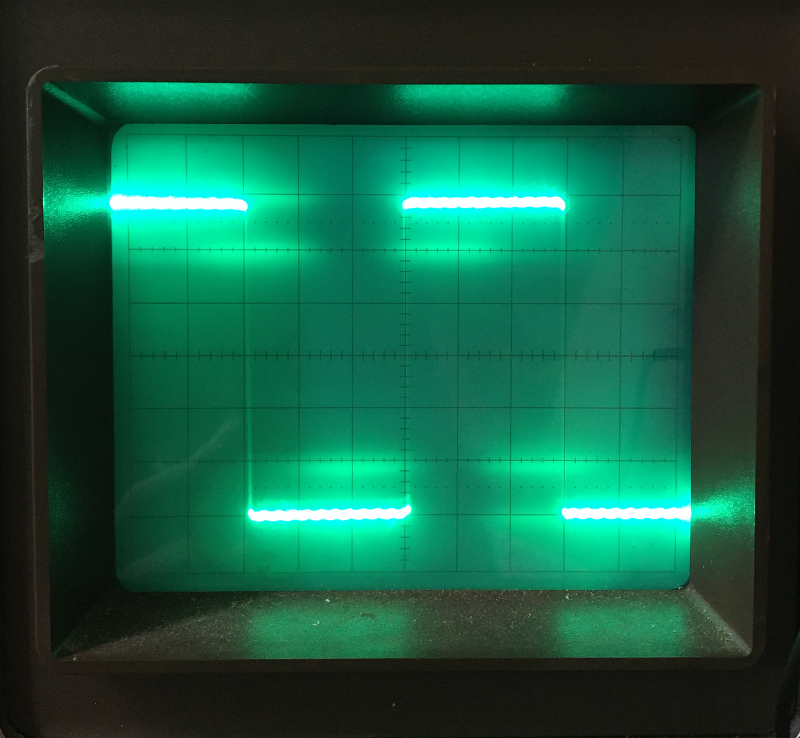

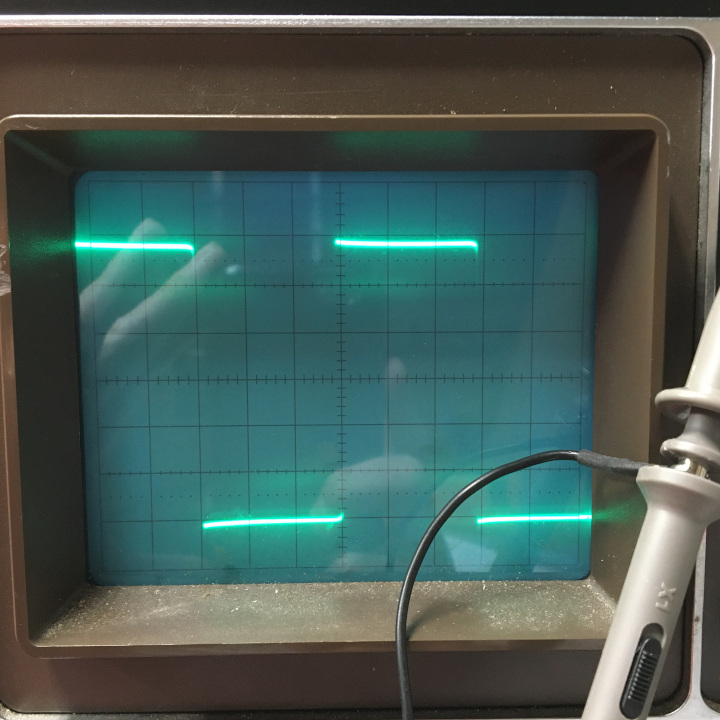

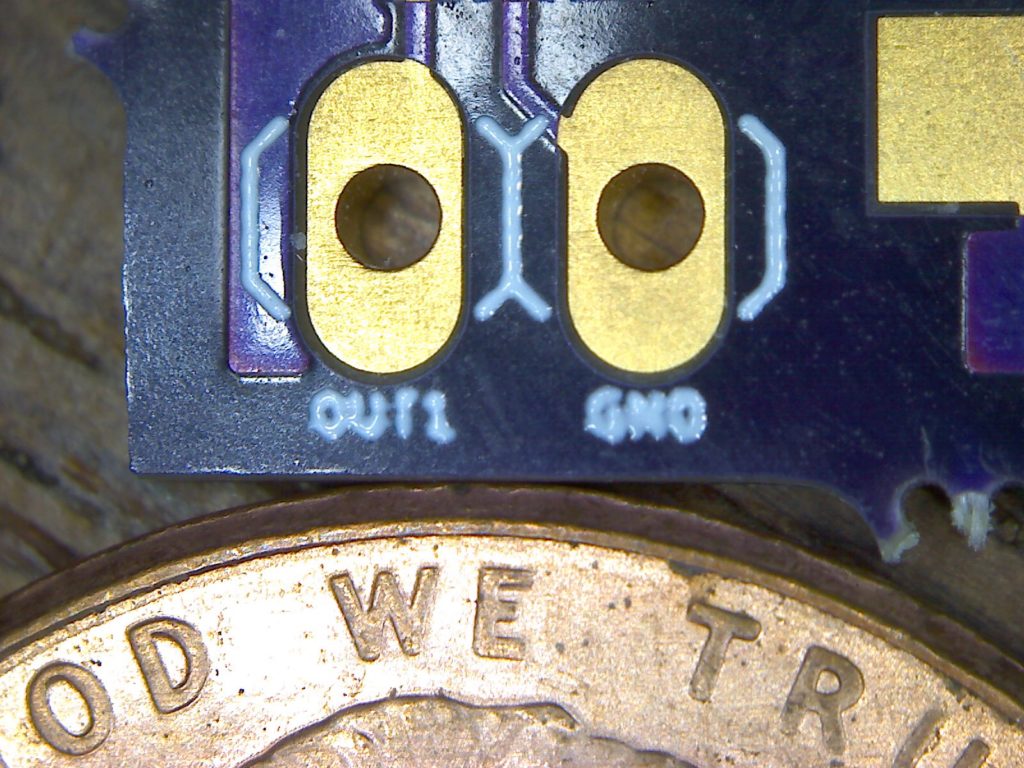

What does this have to do with purple lights? Well, cities across America are under-funded due to the rich not paying their property taxes. Cities have pinched pennies everywhere they can, including by buying the cheapest streetlight bulbs available. Many of these bulbs are defective and turn purple after a few thousand hours of service. So the next time you see a purple streetlight, remember that rich people in your town don’t pay the taxes they’re assessed.