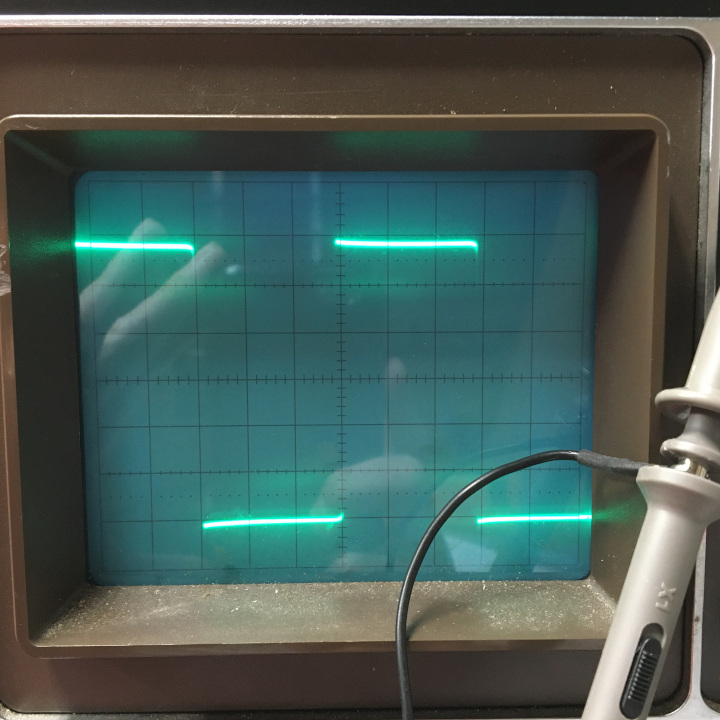

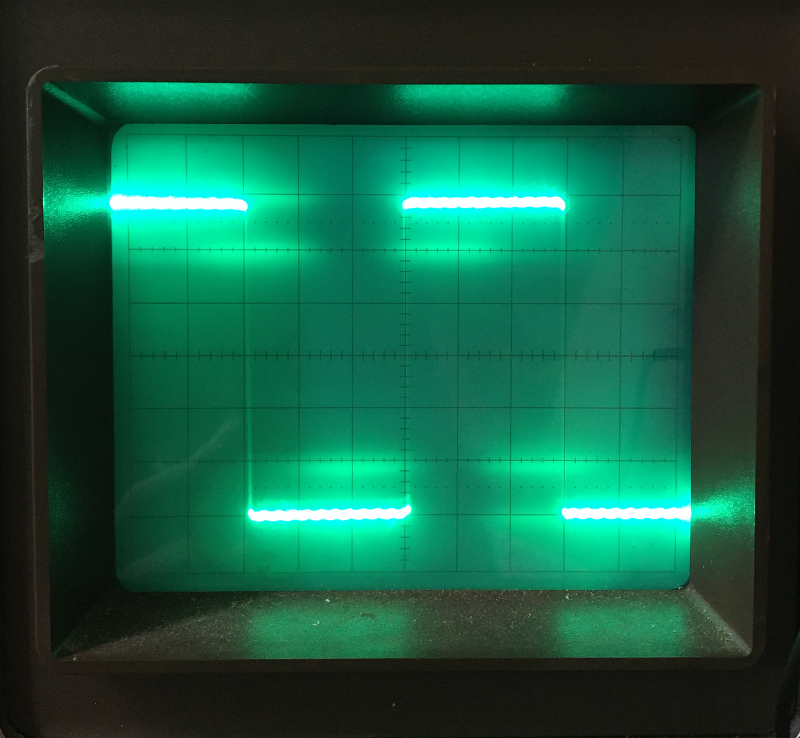

As the previous post hinted, I recently needed to fix my Phillips PM3217 oscilloscope. The problem? Bad vibrations. Or, rather, oscillations on the trace that just shouldn’t be there. Most all oscilloscopes have a test point on the front that is marked “cal” and has a hole to which you clip your oscilloscope probe. This test point provides a square-wave oscillation at a fixed frequency that you can use to adjust the compensation on the probe. I was doing just that when I noticed ripples on the square wave.

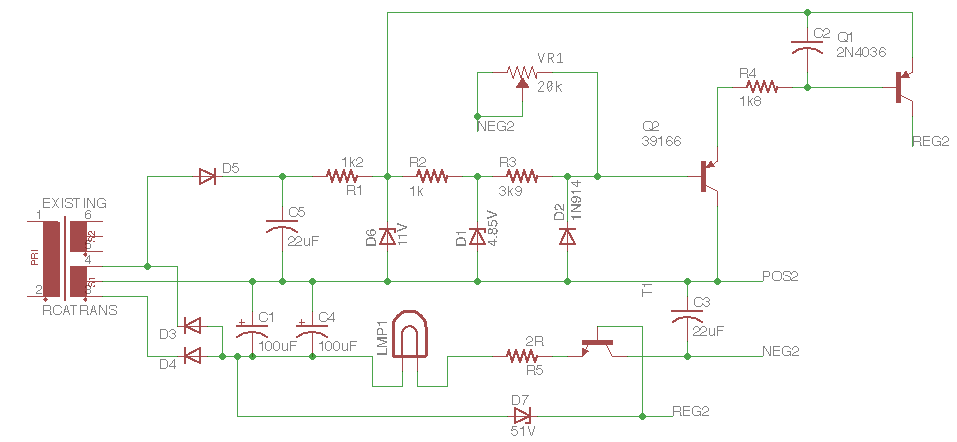

My first thought? Worn-out electrolytic capacitors in the power supply. Why? Probably because that would be the easiest problem to fix. Really, though, it’s a very common problem for electronics of every era. The first thing you should check is always the power supply.

Looking at the service manual, I discovered that the switch-mode power supply oscillates at about 18 kHz. That’s pretty close to the unwanted ripple, so that made me even more sure it was the power supply. Amazingly, my kid could hear the oscillation. I’m old enough that I can’t hear those frequencies, but young ears can!

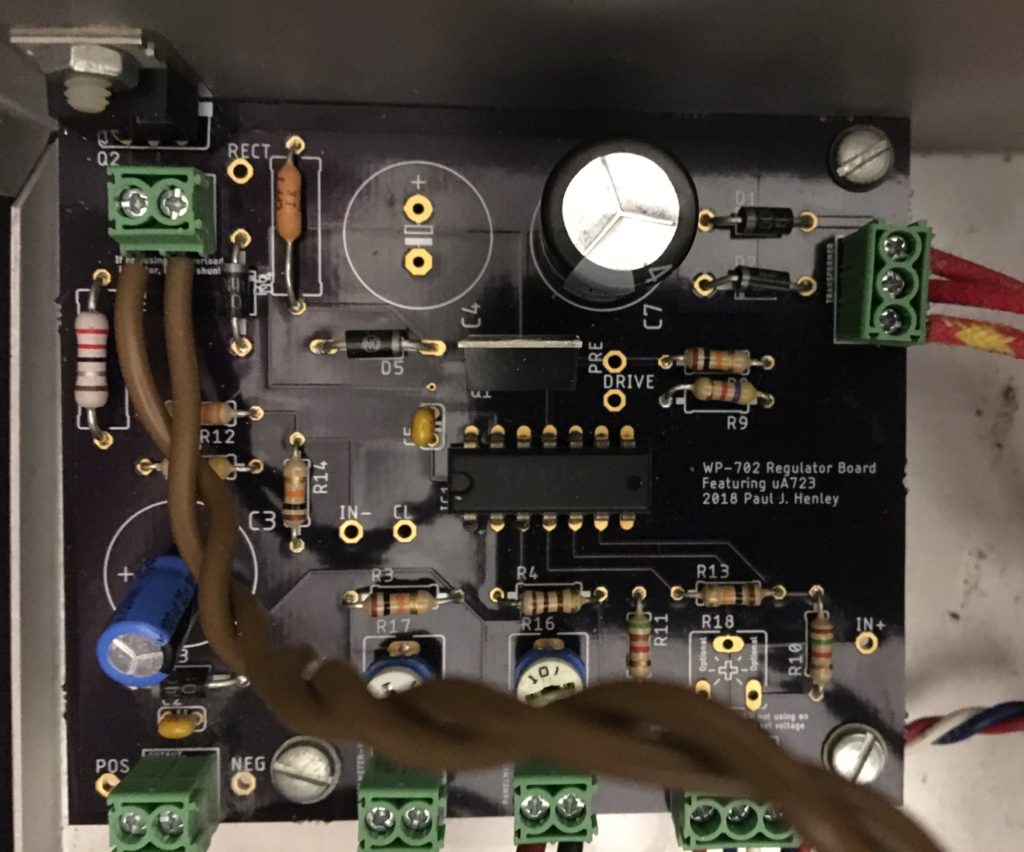

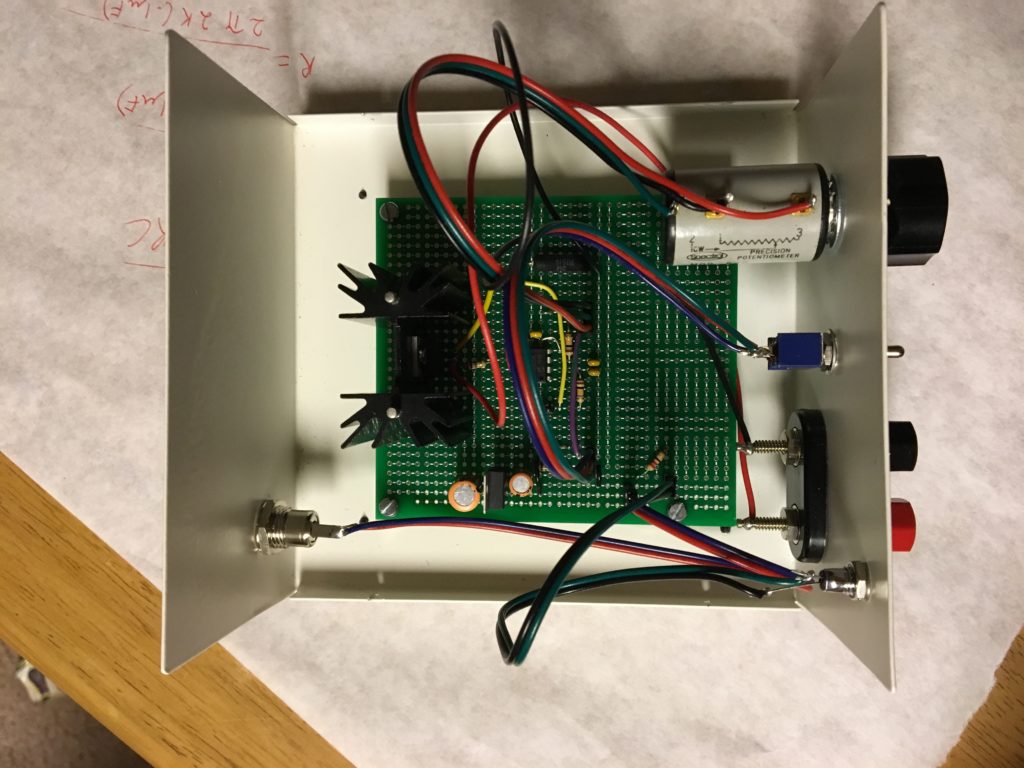

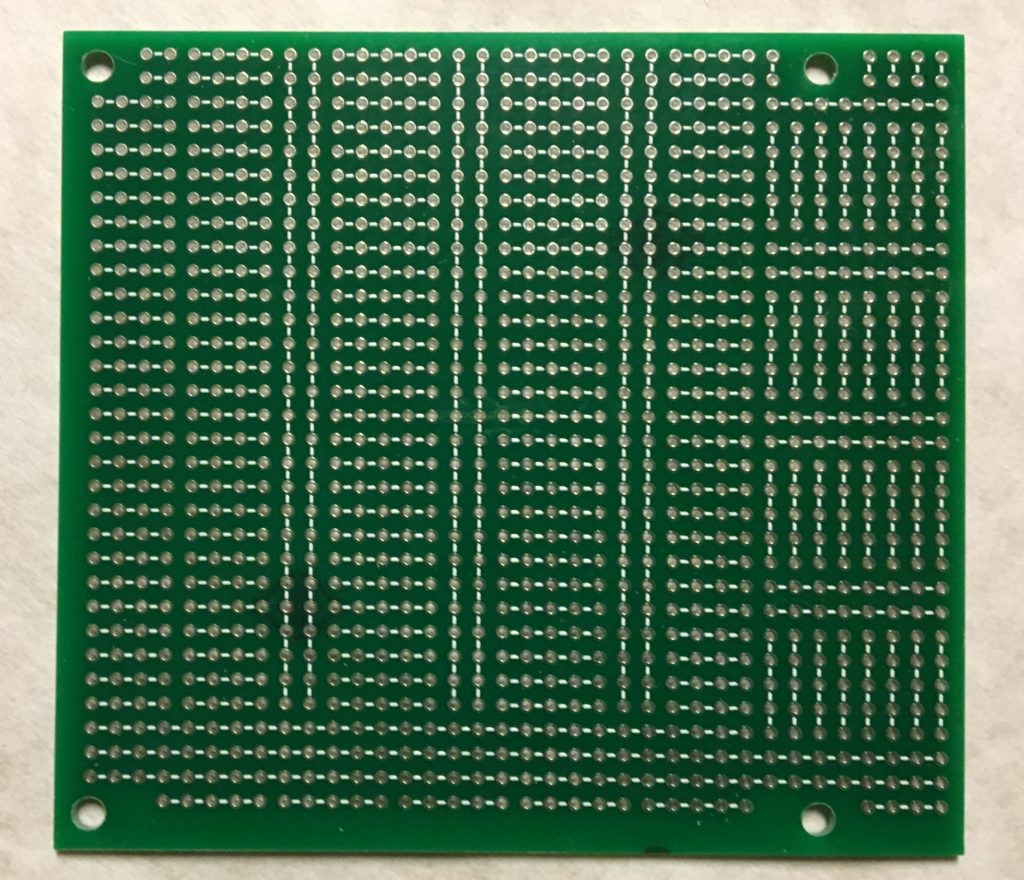

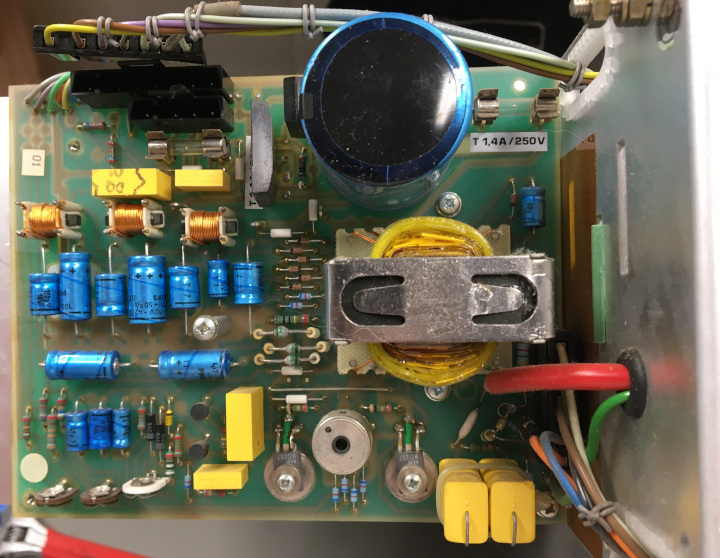

So I opened up the case to take a look. The case opens up with two captive screws. That was refreshing. It’s like they expected you to fix your own equipment, so they made it easy to open. The power supply was easy to find. It’s in the back. A visual inspection turned up no leaking electrolyte, but that doesn’t mean the capacitors aren’t bad. I tested the ESR of each capacitor, and they were almost uniformly too high.

Thankfully I didn’t need to replace that huge cap at the top right. That cap filters the 120 Hz rectified AC input. Those usually aren’t the ones that fail first. It’s the smaller axial caps that are filtering the 18 kHz output. I replaced them with new axial caps, which cost a bit. Axial caps just aren’t popular anymore, so you have to pay a bit for new ones. I got them all from Vishay, from their industrial temperature, low ESR lines.

So did it fix the problem? You bet! Always check the power supply first!