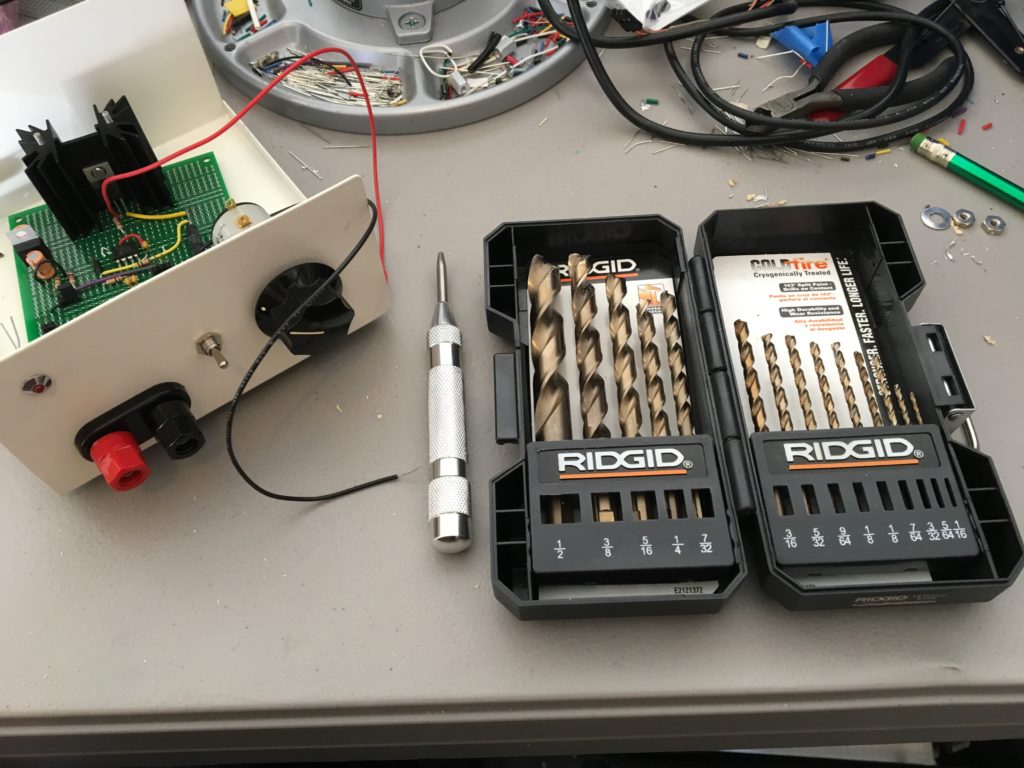

I’ve always struggled with enclosures. Trying to drill holes in those ABS project boxes from Radio Shack with a hand-held power drill is a pain. I had better luck when I had access to a drill press, but that wasn’t often. This time I went metal. The product page at Jameco says this enclosure has a steel top and aluminum body. I used a center punch and then some lightly-used RIDGID ColdFire drill bits and had no problems. The hand drill didn’t have any problem with the aluminum. I guess decent bits and the center punch are the ticket.

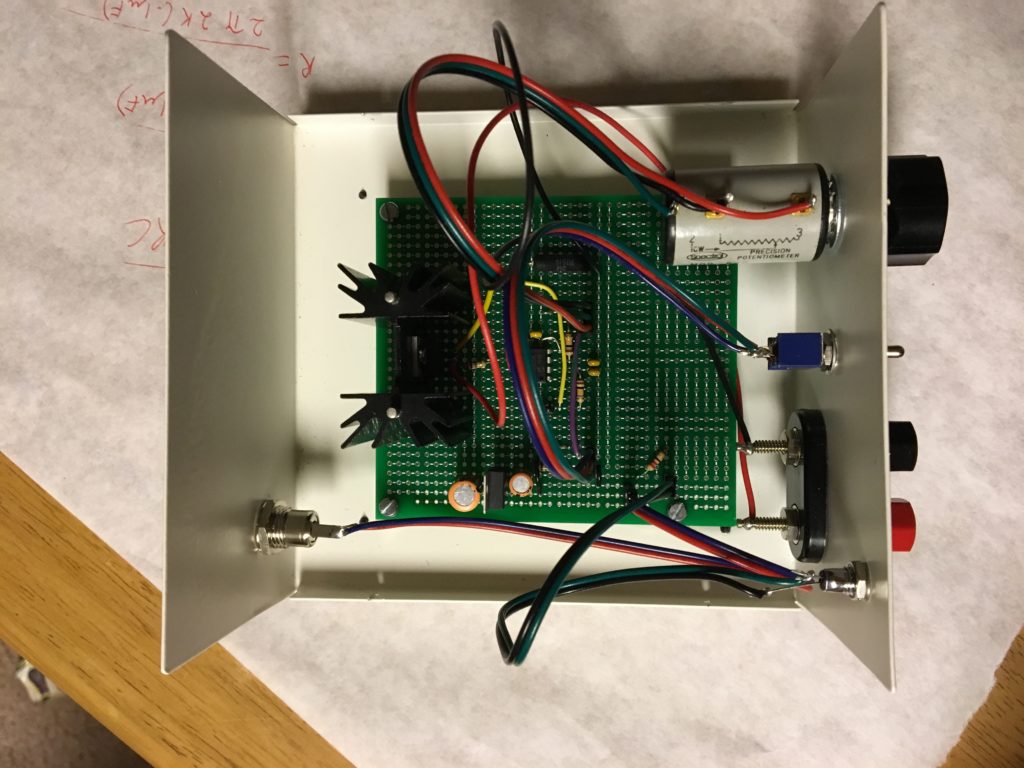

The circuit is pretty simple. An op-amp drives a power MOSFET that dissipates the power as heat. The current passes through a 2-ohm sense resistor on the way out that feeds back to the op-amp. The current level is set by a 10-turn potentiometer I picked up at a hamfest. I soldered it all up on one of those protoboards I made. There are two ranges: 25mA and 2A. You’ll notice I mounted the heat sink upside down because I didn’t want to drill holes in the protoboard. I might change that, but it works fine for now. All told, I’m pleased. I’ve already used it to characterize an old panel meter.